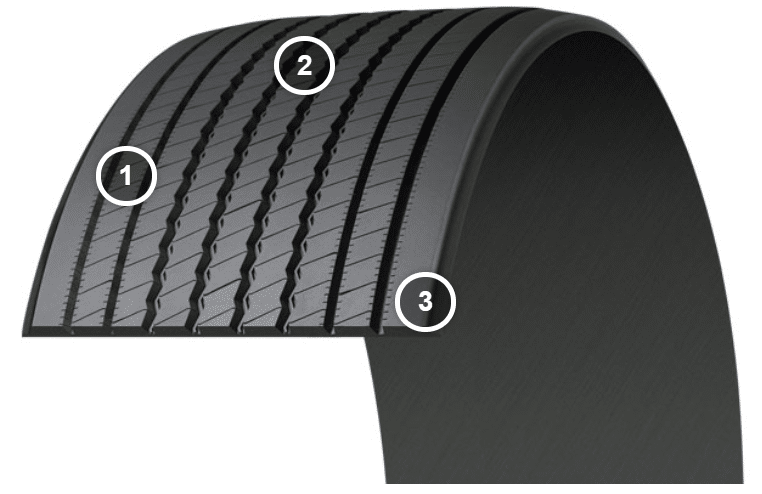

MICHELIN X ONE® XTE® Custom Mold

Trailer position retread / recap optimized to promote stability and resistance to uneven wear for new generation wide-based singles in regional hauling applications.

Wait until we verify sizes...

One size for this tire

Technical specification

| Casing Size | 445/50R22.5 |

|---|---|

| Tread Depth | 16/32 nds |

| MSPN | 38724 |