Ag tire rotation can be beneficial to support tire longevity

Agricultural tire rotation to support tire longevity

SUMMARY:

What is tire rotation?

This practice involves swapping tires between different positions on the vehicle in order to distribute wear and mechanical stress more evenly. In this article, we will explore in detail the situations in which tire rotation can be beneficial, as well as the advantages it offers farmers.

Tire rotation case #1: Tractors

In certain situations, it is possible to swap the front tires of a tractor from one side to the other to support their lifespan.

In countries where people drive on the right, the right tire is generally more exposed than the left. This is because the road is often slightly curved to facilitate water drainage, which causes the right-hand tire to sag on the slope.

This natural curving of the road often forces the driver to compensate by slightly adjusting the steering wheel to prevent the tractor from drifting into the ditch. This constant compensation can lead to uneven tire wear, most noticeable on the right-hand side of the tread.

So, in the event of intensive use on the road and more pronounced wear on one side, it is possible to swap the front tires, i.e. by exchanging their right and left positions.

Front view of tractor

This reduces the exposure of the right-hand tire and helps it to wear more evenly, avoiding premature tire replacement. In addition, even wear may help to reduce vibration and noise, supporting comfort for the driver.

Tire rotation case #2: Twinning

Another circumstance where tire rotation is ideal is twinning (having two tires mounted side-by-side on the same axle). Twinning is mainly used in fields or other unpaved surfaces so there is less stress on the tires than driving on the road, and therefore wear less quickly.

However, it is common practice in some countries to remove tires from twinning to carry out other work, such as transport, which means that the inside tires work more hours, leading to a disparity in wear. As a result, the outer tires are less worn and larger than the others. This size difference puts additional stress on the axle.

To ensure efficient operation of twinning, it is recommended to maintain a proportional level of wear on all four tires. By rotating tires (swapping inner and outer tires on the same axle), you can compensate for this uneven wear and extend the life of the tires. This also reduces the stress on the axle, improving the tractor's stability. An added benefit is that wear on the dual tires maximizes traction efficiency and reduces fuel consumption during field operations.

Tire rotation case #3: Large articulated tractors

In the USA and Brazil, many articulated tractors are fitted with large sets of twin tires.

This configuration generally leads to irregular wear. In fact, due to the large width of these tractors, the two outer tires tend to dig in at the edge of the road. As a result, intensified wear often occurs on these tires. In such circumstances, rotating tires is a good decision. By swapping their position (outside/inside), you should see more even wear and extend the life of the tires.

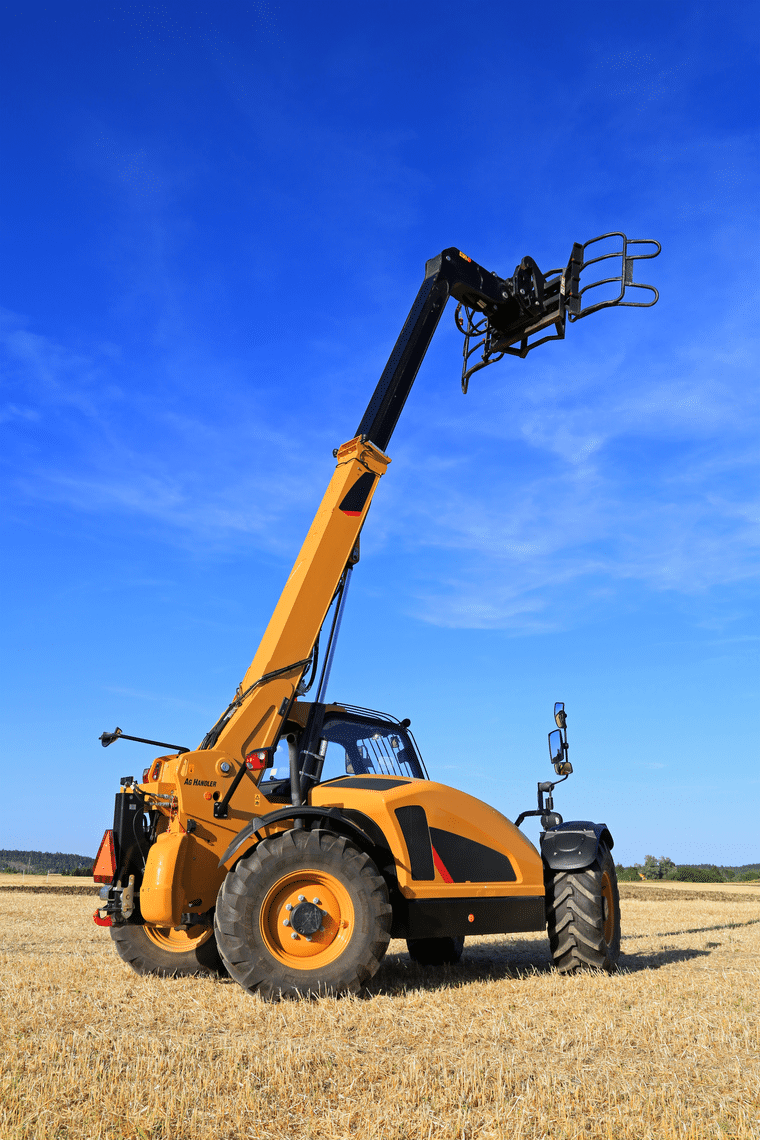

Tire rotation case #4: Telescopic forklifts

Telescopic forklift trucks, which are becoming increasingly common on farms, are multi-purpose machines that perform a variety of tasks, including handling and road transport.

Some are fitted with hitches to transport straw, for example, and then return to the road. As a result, these machines are subject to intensive road use. What's more, they are often used on rugged terrain during handling work.

Nowadays, farms often have a lot of concrete and asphalt. Frequent maneuvering on the different surfaces can lead to greater wear on the front tires, which are under greater stress because they are carrying heavier loads.

As the front tires are the same size as the rear tires, you can swap them when you notice a slight imbalance between the front and rear, usually at mid-wear. In such case, rotating tires ensures that all four wear evenly and support their lifespan.

Ag telescopic forklift

Tire rotation case #5: Self-propelled sprayers

Self-propelled sprayers, with their high ground clearance and narrow tires, are often equipped with steered axles at the front and rear, which can cause alignment problems.

It is not uncommon to notice, when following these vehicles on the road, that the four wheels are not parallel. Over time, the alignment can become slightly faulty, sometimes resulting in irregular wear patterns.

To overcome this problem, it is common practice to rotate the tires, given that the four wheels are generally the same size. This practice helps to compensate for some of the uneven wear.

Conclusion

Tire rotation is a practice that sometimes makes it possible to limit the stress on the most worn tire by exposing the less-worn tire to greater stress, with the objective to extend tire life.

However, in the event of irregular wear on your tires, it is first essential to identify the cause. This could be due, for example, to misalignment in relation to a worn ball joint. Before rotating your tires, we recommend that you first check the alignment and make sure there is no mechanical play.

Need more advice? Discover our tire maintenance and caring guide