computer image

INNOVATION TO ENHANCE YOUR MOBILITY

Michelin believes in putting innovation at the heart of its strategy. It is a major competitive asset that sets us apart from the competition and ensures our Group’s long-term success.

We believe strongly in making innovation a key part of our strategy. Innovation, wherever it comes from, is a crucial driver of our development, of competitiveness, and of longevity for your company or business activities.

The Michelin Technology Center employs more than 6,000 people in over 350 different areas of expertise, including researchers, engineers, developers and testers. More than 10,200 patents are active worldwide, having been filed by the Michelin Technology Center. We know that the R&D of new products, new materials and new technologies matters to your business. Our new technologies make tires safer, longer-lasting, more cost-effective and more environmentally friendly over the long run.

MICHELIN TECHNOLOGY

Edito carcasse michelin Tire

Carcasse Michelin Poids Lourd

Edito factory visit 244 Tire

pneu michelin

Edito chimie Tire

edito ecosystème groupe mi tire

Edito carcasse michelin Tire

Carcasse Michelin Poids Lourd

THE TIRE CASING

Casing-related innovations continually deliver greater tire durability and make a direct contribution to lowering your fuel consumption.

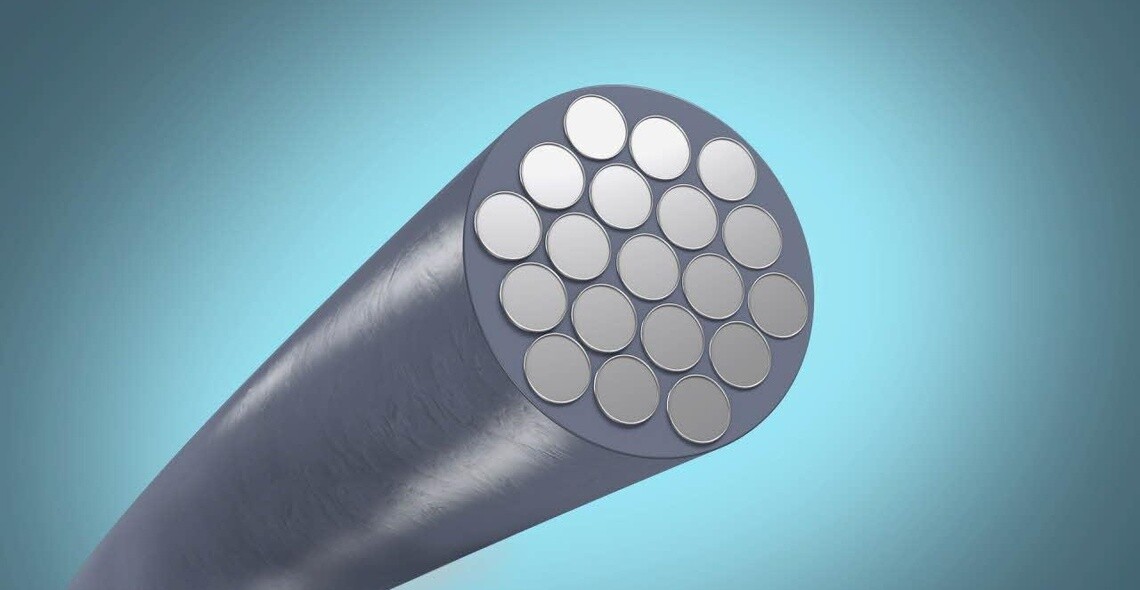

INFINICOIL technology

MICHELIN DURABILITY AS THE MILES TICK BY

A continuous steel wire – up to 1/4 mile – is wrapped around the tire circumference to make it more stable and durable throughout its service life. The tire’s enhanced durability at a higher load index or in harsher usage conditions means you can drive with complete confidence.

POWERCOIL technology

MICHELIN DURABILITY WITH IMPROVED ROLLING RESISTANCE

A new generation of lighter yet more robust steel cables is used in the casing to deliver improved resistance to distortion and damage. POWERCOIL technology therefore reduces rolling resistance and fuel consumption for better durability.

Edito powercoil technology 1 Tire

Pneu Michelin technologie

DURACOIL technology

A REINFORCED BEAD FOR GREATER ROBUSTNESS

We make high-quality products that last longer. To achieve this goal, this technology adds a new type of reinforced section between the tire and the wheel for greater robustness. Our premium nylon protects the bead structure and makes it more stable while driving.

Edito duracoil technology Tire

Edito michelin ultraflex Tire

michelin ultraflex zoom

Michelin Ultraflex Technology

Tractor tire equipped with central tire inflation system (CTIS)

Presseveranstaltung

MICHELIN Ultraflex Technologies

PRODUCTIVITY GAINS AND SOIL PROTECTION

Michelin rose to this challenge in 2004 by inventing MICHELIN Ultraflex, a game-changing innovation that allows agricultural tires to operate at a lower pressure and therefore protect the soil, thus allowing for higher crop yields.

For improved soil health and better harvests, it is important to avoid or minimize soil compaction.

MICHELIN Ultraflex technology solves both halves of this equation: less pressure = less compaction = more soil protection = higher yields.

A British study by Harper Adams University shows that utilizing tires with MICHELIN Ultraflex technology can deliver crop yield gains of 4% or higher. As an illustration, when a farm produces a yield of 3 tons per acre and sells its wheat harvest for 225 dollars per ton, this is equivalent to a gain of 29 dollars a year, per acre.

MICHELIN Ultraflex technology is already 10 years old but its future looks bright: MICHELIN AXIOBIB 2 tires, also designated AIR SYSTEMS READY, are designed to work with a remote inflation system (CTIS) enabling users to monitor and adapt tire pressure to the terrain and usage conditions.

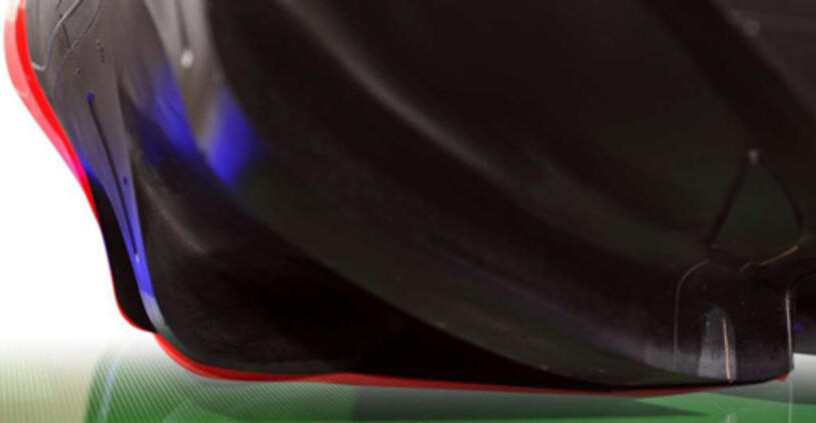

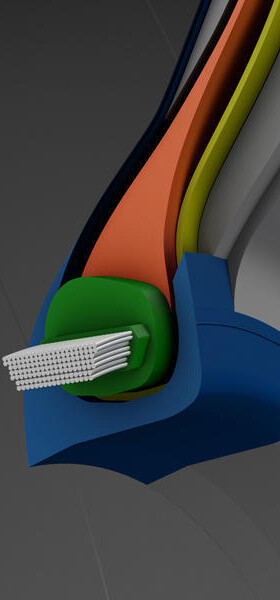

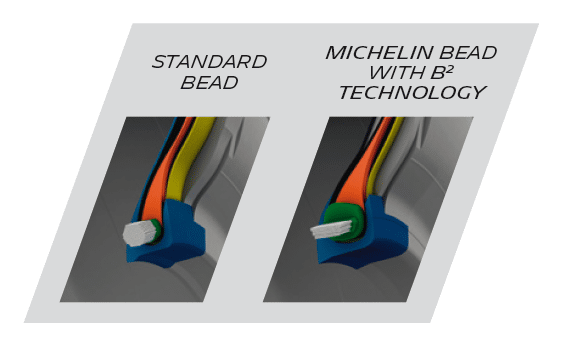

B2 technology

DEAL WITH EXTREME EARTHMOVER CONDITIONS

To boost productivity in mines and quarries, but also in construction and handling operations, machines and tires alike are regularly pushed to their limits. The exclusive B² technology from Michelin makes the bead area more robust and therefore increases the service life of the tires.

The tire/rim interface is really put to the test when high torque is applied or when carrying heavy loads. MICHELIN tires featuring B² technology have a wide metal bead wire that increases the area in contact with the rim. The strength of the bead area is enhanced and there are fewer rotations on the rim.

Dig more, carry more: B² technology delivers up to 20% more torque*, making machines more productive.

*Internal study compared with standard MICHELIN tires. Specific values according to size.

Edito technology b2 Tire

Edito technob2 standard Tire

schemas technob2 standard

NRF technology

COPE WITH THE EXTREME CONDITIONS OF UNDERGROUND MINING

Resistance to harsh conditions is improved by: • 2 additional plies added to the tire structure which contain nylon cords cross-woven throughout the rubber for more resistance and robustness. • New cables in the working plies for enhanced resistance to impacts and better protection against oxidation.

background factory visit 244 tire

THE TREAD

Cutting-edge technologies for our tire tread, with patterns that evolve and adapt as tires wear to boost service life and performance.

REGENION technology

MICHELIN GRIP, MILE AFTER MILE

Tread designs that self-regenerate, mile after mile, thanks to 3D metal printing techniques, giving you the grip you need over the service life of your tires and in all conditions. New sipes appear as your tires wear for improved mobility. In 2018, the two Michelin engineers behind REGENION technology won the European Inventor Award in the Industry category.

edito chimie tire

MATERIALS

Cutting-edge technologies for our tire tread, with patterns that evolve and adapt as tires wear to boost service life and performance.

Advanced Compounding Technology

MICHELIN LONGEVITY, DAY AFTER DAY

A unique material created by an innovative process in which some tread components are blended when in a liquid state. The material this creates is more homogeneous, helping to get more miles out of the tire.

Advanced Compounding Technology

MORE SILICA EQUALS LOWER FUEL CONSUMPTION

By adding a high percentage of silica to the tread blend, Michelin has managed to push the limits of rolling resistance so that you can save fuel, without compromising on tire longevity.

ckcfnho23031e01mhdi223vuz edito ecosyste me groupe mi tire full

BEYOND THE TIRE

With related services and new types of products, MICHELIN tire innovations make tires safer and longer-lasting, while increasing cost effectiveness.

Edito michelin x tweel ssl all terrain Tire

TWEEL airless technology

NO MAINTENANCE. NO COMPROMISE.

A MICHELIN® X® TWEEL® airless radial tire is a single unit that replaces the current tire and wheel assembly. There is no need for complex mounting equipment and once they are bolted on, there is no air pressure to maintain. The unique energy transfer within the poly-resin spokes helps reduce the “bounce” associated with pneumatic tires, while providing outstanding handling characteristics. They are designed to perform like pneumatic tires, without the inconvenience and downtime caused by flat tires. It therefore requires no pressure maintenance and cannot puncture. It is a technology that substantially reduces machine downtime. It also provides unparalleled convenience for the operators of farm and public works vehicles (construction or handling) equipped with airless tires.

RFID technology

An RFID (Radio Frequency Identification) chip is a smart electronic component that receives and transmits radio signals (wirelessly), so a product can be identified in a unique, standard way.

The identification of all MICHELIN tires using reliable miniature RFID chips fitted in the tires means they can be tracked throughout their life cycle, from manufacturing to recycling. This patented technology is being marketed so that it becomes widespread in the tire industry.

Edito rfid logo 1 Tire

Pneu Michelin technologie

Edito operating advice Tire

Zoom sur les roues d'un camion équipé en pneus Michelin

As the only part of the vehicle in contact with the ground, a tire has the potential to supply unique, detailed data throughout its life. Using RFID technology, Michelin has chosen to make tires "speak" by connecting them to a broader ecosystem, with the aim of unlocking infinite innovation and value creation potential.

The Michelin Group will be accelerating the connectivity of its products in order to connect all MICHELIN tires, including passenger car tires, by 2023. At this moment, 90% of MICHELIN truck tires are already fitted with RFID chips in North America and Europe.

mems4 key visual purchased img

MEMS Evolution 4

INCREASING YOUR EFFICIENCY HAS NEVER BEEN SIMPLER

The fourth generation of the famous "Michelin Earthmover Management System," a TPMS solution for mining vehicles, takes connected tires one step further. MICHELIN® MEMS®4 is a powerful monitoring tool for tires and usage conditions. It combines downtime-fighting features, innovative equipment, and seamless connectivity to increase profits and reduce downtime by protecting your people, tires and equipment.