- Long Distance

Usage

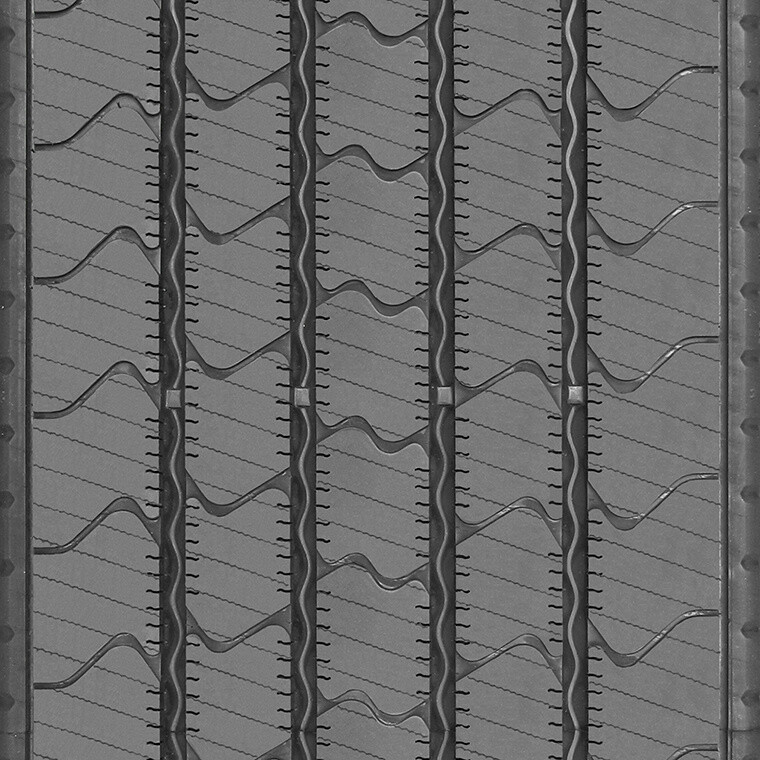

MICHELIN X® LINE ENERGY T Siped Pre-Mold Retread

A premium trailer position siped retread / recap for line haul applications, designed to provide fuel efficiency* and long, even wear.

Usage

-

11R22.5

-

11R22.5

-

11R22.5

-

11R22.5

-

11R24.5

-

11R24.5

-

11R24.5

-

11R24.5

-

225/70R19.5

-

225/70R19.5

-

245/70R19.5

-

245/70R19.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/80R22.5

-

255/80R22.5

-

265/70R19.5

-

265/70R19.5

-

265/70R19.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

285/70R19.5

-

285/70R19.5

-

285/70R19.5

-

285/70R19.5

-

11R22.5

-

11R22.5

-

11R22.5

-

11R22.5

-

11R24.5

-

11R24.5

-

11R24.5

-

11R24.5

-

225/70R19.5

-

225/70R19.5

-

245/70R19.5

-

245/70R19.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/70R22.5

-

255/80R22.5

-

255/80R22.5

-

265/70R19.5

-

265/70R19.5

-

265/70R19.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

285/70R19.5

-

285/70R19.5

-

285/70R19.5

-

285/70R19.5

WHAT IS RETREAD / RECAP?

The X® Line Energy T Siped Pre-Mold Retread utilizes Michelin Retread Technologies’ 9-step manufacturing process to ensure the retread, sometimes referred to as a recap, recapped tire or remold, meets new-tire manufacturing standards. By having your fleet’s tires retreaded or recapped, you can protect your bottom line and the planet by helping reduce the millions of tires that are discarded in landfills each year. Click here to find a Michelin Retread tire dealer near you.

WHY THIS RETREAD / RECAP?

RESISTS ONSET OF UNEVEN WEAR

– New siping technology and decoupling groove to support even wear on the trailer axle position.

– Wider tread widths available - Stress on the retread / recap is more evenly distributed for long, even tread life.

FUEL SAVINGS

– Advanced compound tread - The Michelin X® Line Energy T Pre-Mold retread / recap provides 5.0% lower rolling resistance vs. the Michelin XT-1® AT Pre-Mold retread / recap. **

– Meets SmartWay® requirements

LOWER TOTAL COST OF OWNERSHIP

– Designed for fuel efficiency, long tread life and even wear to drive competitive advantage for the fleet.

– Variable groove bottom features to help resist stone retention for longer wear

Also available as a Pre-Mold retread / recap.

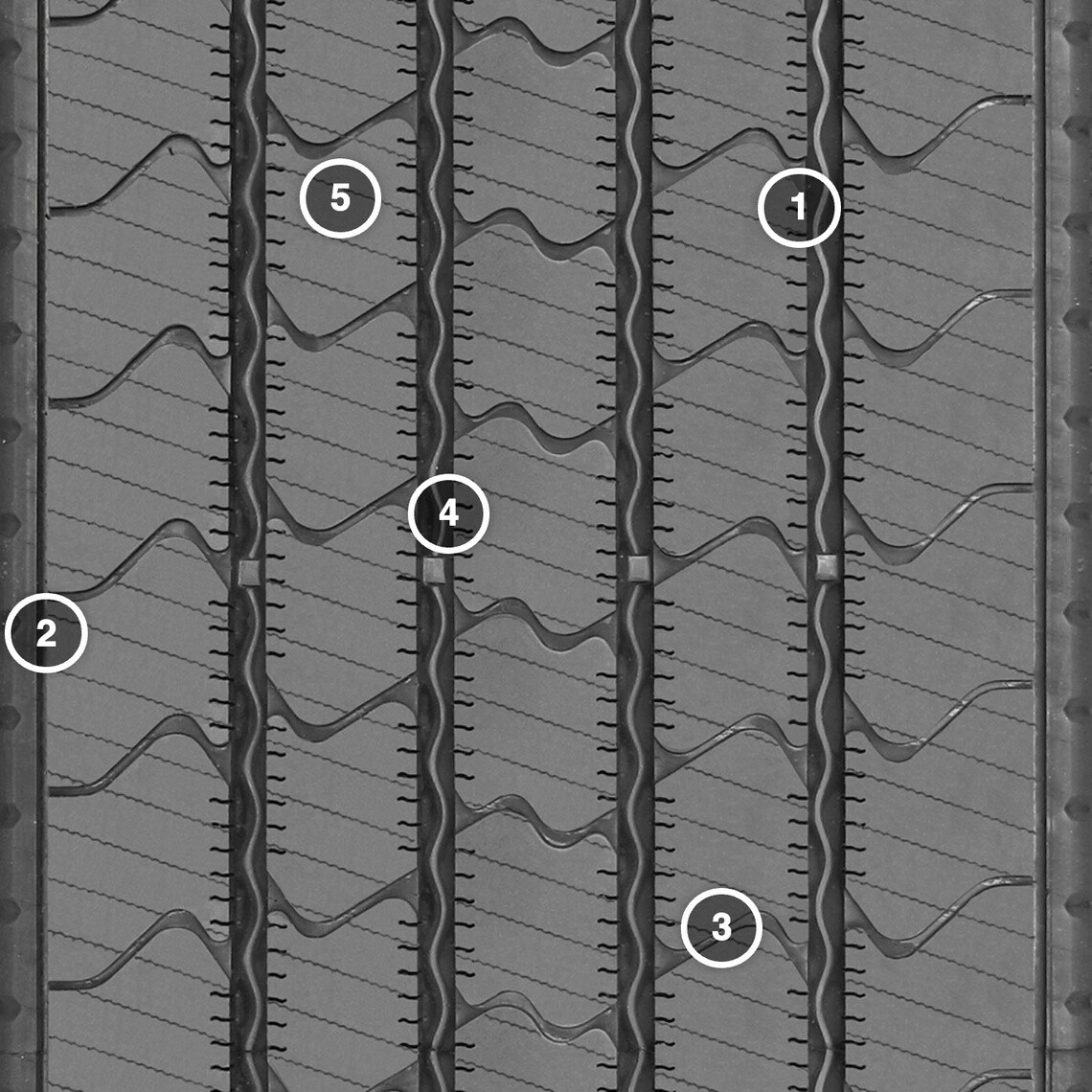

BENEFITS AND FEATURES

1. New siping technology

Supports even wear on the trailer axle position.

2. Decoupling groove

Supports even wear on the trailer axle position.

3. Advanced compound tread

Meets SmartWay® requirements.

4. Variable groove bottom

Help resist stone retention.

5. Total Cost of Ownership

Designed for fuel efficiency, long tread life and even wear to drive competitive advantage for the fleet.

Michelin X® Line Energy™ T Siped Pre-Mold / Recap Retread

REFERENCE MATERIALS - DOCUMENTS

Michelin X® LINE ENERGY T Siped Pre-Mold Retread / Recap Product Sheet

Michelin Truck Tire Data Book

Michelin Retread Technologies, Inc. National Limited Warranty and Enhanced Michelin X One® Casing Warranty

Michelin Retread Technologies Quick Reference Tread Guide

- Technical specification

Technical specification

| Casing Size | 11R22.5 |

|---|---|

| Tread Width | 220 mm |

| Tread Depth | 11/32 nds |

| MSPN | 64782 |

Pre Mold Process

Also known as a "pre-cure" process. Tread rubber used in this process is molded and pre-cured by the tread rubber manufacturer, Michelin Retread Technologies (MRT). The appropriate tread is selected – design, width, thickness – and applied to a prepared casing. The casing is prepared by placing a cushion gum bonding layer between the tread and casing. The tire then moves to the chamber for curing.

* Based on external rolling resistance tests of the Michelin X® Line Energy T Pre-Mold retread / recap in 230mm width and current Michelin XT-1® AT Pre-Mold retread / recap in 225mm width using ISO 28580 test method in tire size YOK RY617 295/75R22.5. Actual on-road fuel saving results may vary, and may be impacted by many factors, to include road conditions, weather, environment, combination of steer and trailer tires used, driving habits, tire size, equipment and maintenance.

** Actual on-road fuel saving results may vary, and may be impacted by many factors, to include road conditions, weather, environment, combination of steer and trailer tires used, driving habits, tire size, equipment and maintenance.