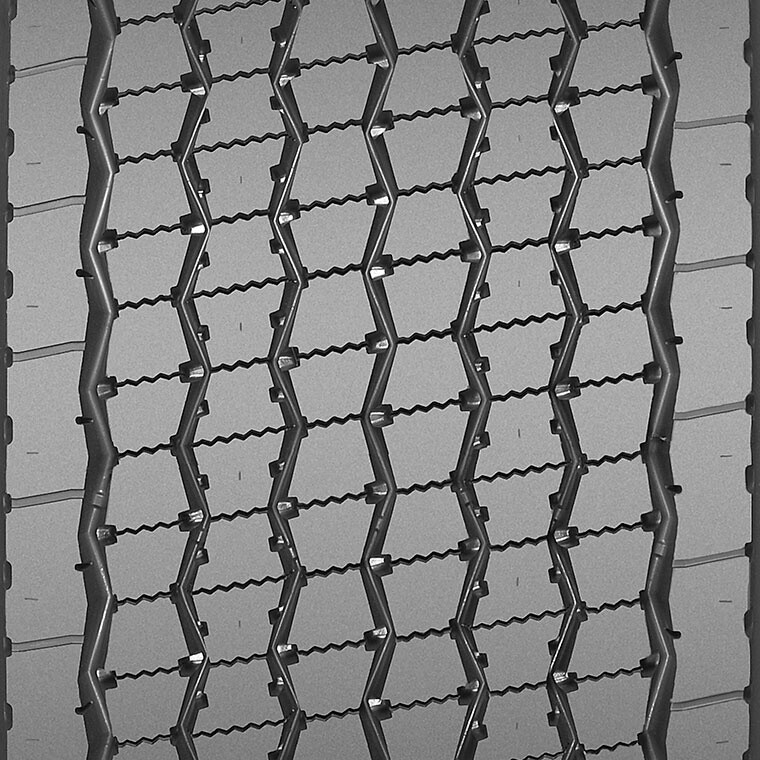

MICHELIN X ONE® LINE ENERGY D Pre-Mold Retread

SmartWay® fuel economy* with long tread life and excellent traction in a line haul energy drive retread / recap..

Wait until we verify sizes...

One size for this tire

Technical specification

| Casing Size | 445/50R22.5 |

|---|---|

| Tread Width | 375 mm |

| Tread Depth | 22/32 nds |

| MSPN | 88700 |