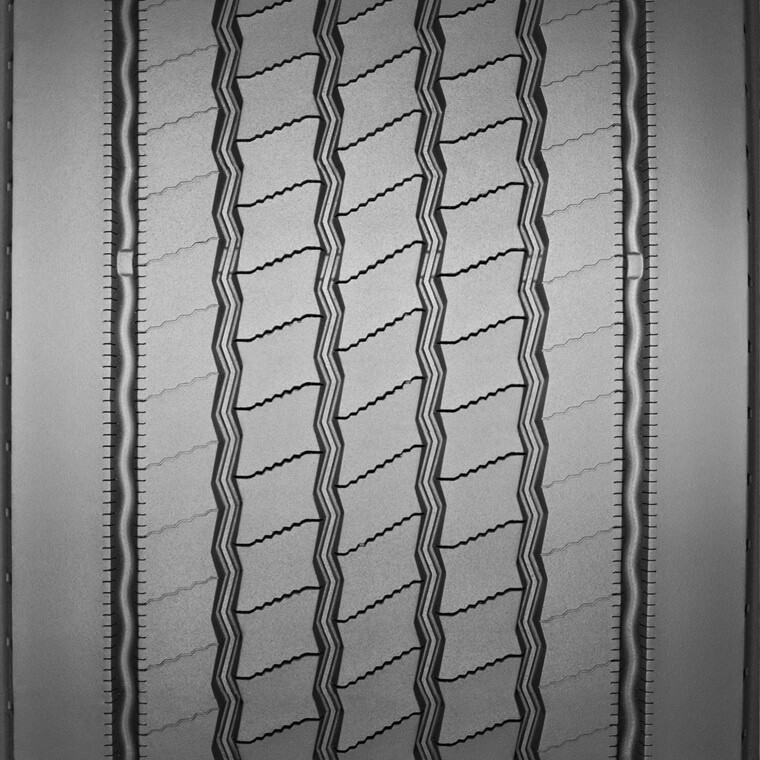

MICHELIN X ONE® MULTI ENERGY T Pre-Mold Retread

A SmartWay® verified trailer position retread / recap which ensures the right balance of outstanding removal mileage, reduced irregular wear and fuel efficiency, optimized for regional applications.

Wait until we verify sizes...

4 sizes for this tire

Technical specification

| Casing Size | 445/50R22.5 |

|---|---|

| Tread Width | 375 mm |

| Tread Depth | 15/32 nds |

| MSPN | 06071 |