MICHELIN X One XDS2 Pre-Mold Retread

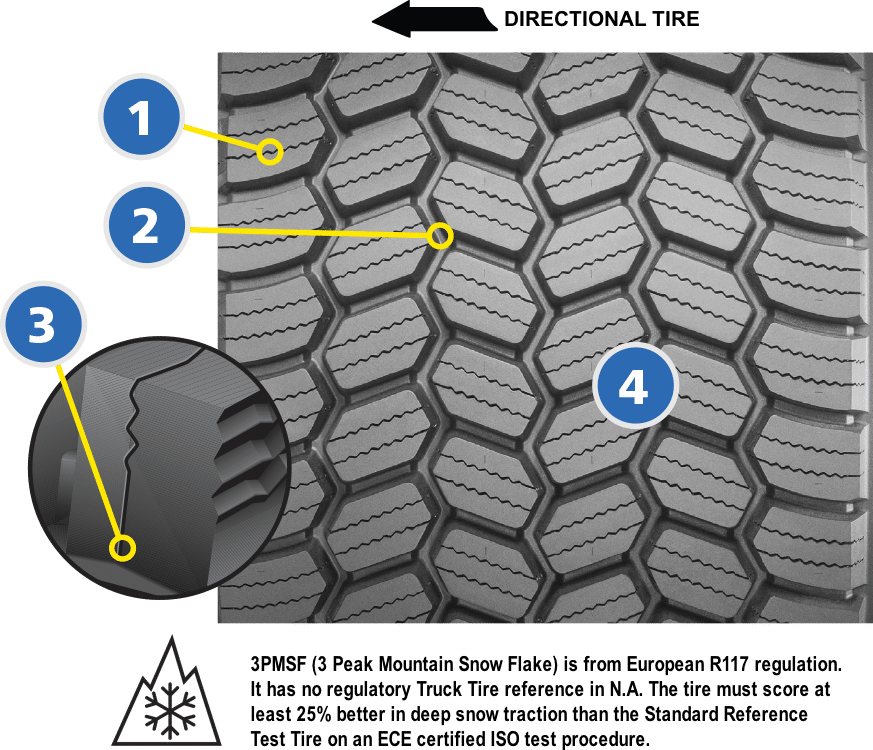

The Michelin X One XDS2 Pre-Mold drive axle retread is designed for extreme winter conditions to promote driver confidence and security while capitalizing on the enhanced fuel and weight savings of a new generation wide based tire.

Wait until we verify sizes...

2 sizes for this tire

Technical specification

| Casing Size | 445/50R22.5 |

|---|---|

| Tread Width | 375 mm |

| Tread Depth | 25/32 nds |

| MSPN | 14270 |