- Durability

- Traction

Usage

MICHELIN XDY-EX Pre-Mold Retread

Delivers exceptional durability and traction in demanding off-road applications.

Usage

-

11R22.5

-

11R22.5

-

11R22.5

-

11R24.5

-

11R24.5

-

11R24.5

-

12R22.5

-

12R22.5

-

12R22.5

-

12R24.5

-

12R24.5

-

12R24.5

-

275/70R22.5

-

275/70R22.5

-

275/70R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

285/75R24.5

-

285/75R24.5

-

285/75R24.5

-

295/80R22.5

-

295/80R22.5

-

295/80R22.5

-

305/70R22.5

-

305/70R22.5

-

315/80R22.5

-

315/80R22.5

-

315/80R22.5

-

11R22.5

-

11R22.5

-

11R22.5

-

11R24.5

-

11R24.5

-

11R24.5

-

12R22.5

-

12R22.5

-

12R22.5

-

12R24.5

-

12R24.5

-

12R24.5

-

275/70R22.5

-

275/70R22.5

-

275/70R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R22.5

-

275/80R24.5

-

275/80R24.5

-

275/80R24.5

-

285/75R24.5

-

285/75R24.5

-

285/75R24.5

-

295/80R22.5

-

295/80R22.5

-

295/80R22.5

-

305/70R22.5

-

305/70R22.5

-

315/80R22.5

-

315/80R22.5

-

315/80R22.5

WHAT IS RETREAD / RECAP?

Sometimes referred to as a recap, recapped tire or remold, retread is a tire tread used in the remanufacturing process of a worn tire. The XDY-EX Pre-Mold Retread utilizes Michelin Retread Technologies’ 9-step manufacturing process to ensure retreaded or recapped tires meet new-tire manufacturing standards – protecting your bottom line and the planet. Having your fleet’s tires retreaded or recapped can help reduce the millions of tires that end up in landfills annually. Click here to find a Michelin Retread tire dealer near you.

WHY THIS RETREAD / RECAP?

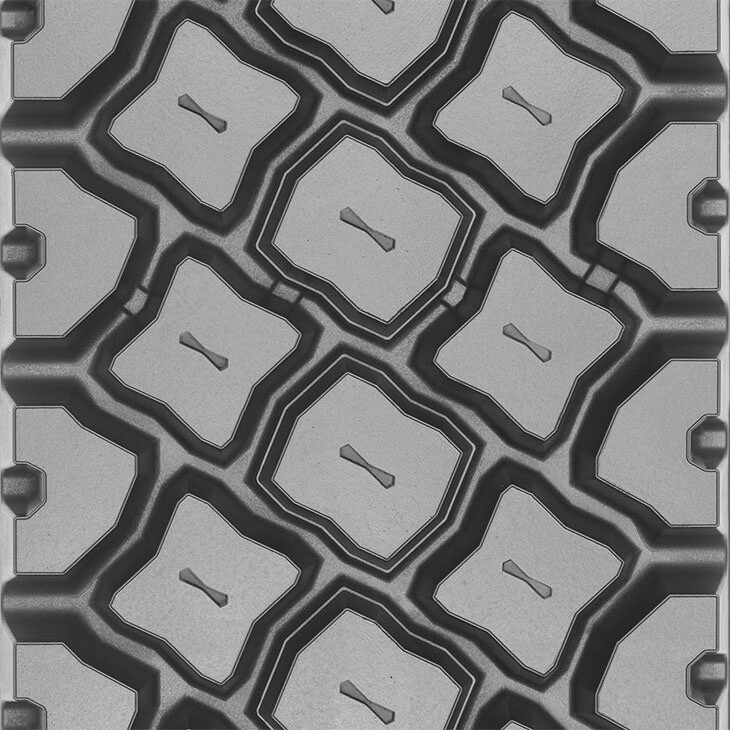

Driving confidence for the challenging off-road conditions of construction, logging, and mining is delivered through an optimized retread / recap, using a raised block sculpture, and deep 32/32nds of tread depth. This combination is designed to deliver exceptional traction in demanding environments.

Long tread life is delivered using proprietary compound technology, that provides exceptional wear resistant properties, alongside stone ejector ledges to reduce the hazards of stone drilling.

32/32nds original tread depth

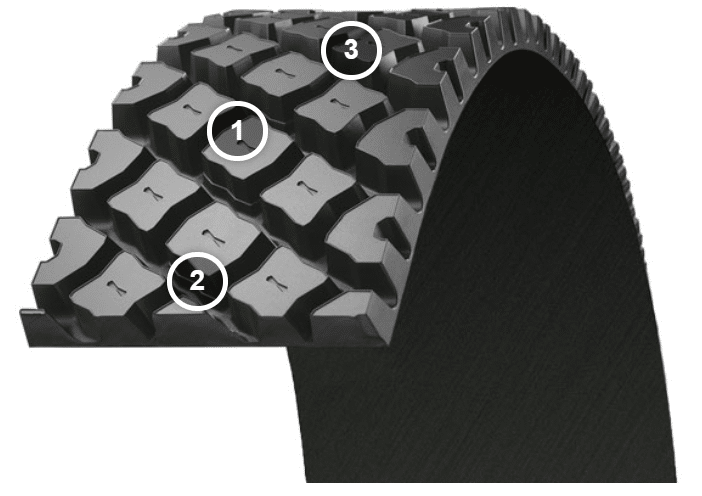

BENEFITS AND FEATURES

1. Proprietary Compound Technology

Long Tread Life – Delivers exceptional wear resistant properties.

2. Stone Ejector Ledges

Durability – Placed on the sides of the tread grooves to reduce stone retention.

3. Optimized Tread Design

Confident Handling – Optimized for extra traction.

Michelin XDY-EX Pre-Mold Retread / Recap

REFERENCE MATERIALS - DOCUMENTS

XDY-EX Pre-Mold Retread / Recap Product Sheet

Michelin Truck Tire Data Book

Michelin Retread Technologies, Inc. National Limited Warranty and Enhanced Michelin X One Casing Warranty

Michelin Retread Technologies Quick Reference Tread Guide

- Technical specification

Technical specification

| Casing Size | 11R22.5 |

|---|---|

| Tread Width | 220 mm |

| Tread Depth | 32/32 nds |

| MSPN | 08560 |

Pre Mold Process

Also known as a "pre-cure" process. Tread rubber used in this process is molded and pre-cured by the tread rubber manufacturer, Michelin Retread Technologies (MRT). The appropriate tread is selected – design, width, thickness – and applied to a prepared casing. The casing is prepared by placing a cushion gum bonding layer between the tread and casing. The tire then moves to the chamber for curing.