Michelin X Line Energy Z+ tire in foreground

Today’s technology makes it easier than ever for fleet owners to manage their assets and maximize their efficiency.

One methodology to do this is to consider the Total Cost of Ownership (TCO) of the products used by the fleet. TCO considers all the costs associated with a particular product, more than just the purchase price.

With tires, in the past, fleets used the Cost per Mile (CPM) method to try to minimize their tire costs (and many other costs as well). This method takes the cost paid for tires and divides them by the typical miles driven before needing to replace them.

Although CPM works pretty well, it has a tendency to look at things in silos, and it could lead to less-than-optimal practices.

Jim Garrett – Product Category Manager, Michelin North America

There's more to consider than just tire costs

Lets use purchasing a truck to show an example of the limitations of CPM. Using CPM would simply take the purchase price of the vehicle and divide it by the miles driven before replacing it. But the price isn’t the only thing to consider. Trucks are impacted by other things, that play a big and important role in which is the most cost-effective: fuel, preventive maintenance, and replacement parts are just a few other things to consider.

Although one truck may cost less at the dealership, if it gets significantly lower fuel efficiency or has shorter maintenance intervals or the parts are more expensive and hard to find – the overall cost of running that cheaper truck could end up being significantly more. TCO attempts to take into account direct and indirect costs (or hidden costs) associated with using the truck to help fleet owners make a better decision about which truck is a better value.

It's much the same way with purchasing tires – you should analyze using TCO. CPM of tires is relatively easy to calculate but just like with evaluating the cost of a truck, CPM does not tell the whole story and can lead to a poor decision. For tires, the most important factors in TCO are purchase price, runout miles, fuel economy and cost associated with maintenance of the tires – including cost of a tire-related breakdown.

Tire TCO = cost of tires + fuel used + maintenance costs. This can be calculated on an annual basis or per mile basis.

Fuel savings and driving graphic

Most fleets understand CPM very well and calculate it to easily determine that a tire which costs 10% more and lasts 15% longer is a better value. This is why almost all larger fleets run premium tires. They have tried to go with cheap tires and found that they just don’t last, and cost more in the end.

Think about this, the money spent in fuel over the life of a set of long-haul tires is about 10-15 times more than the cost of the tires, depending on the price of fuel. In fact, fuel is about ¼ of the annual operating cost of a tractor trailer1. Since tire rolling resistance accounts for about 1/3 of the energy needed to move your vehicle2, it only makes sense to consider fuel use as part of tire TCO.

At Michelin, we have several lines of fuel-savings tires with low rolling resistance. In line-haul, we call them Michelin X® Line Energy™, and in regional tires we call them Multi Energy.

– said Garrett

Does lower rolling resistance save tire costs?

Lets take a look at an example of TCO for tires using Michelin’s Fuel Savings Calculator. Check it out yourself!

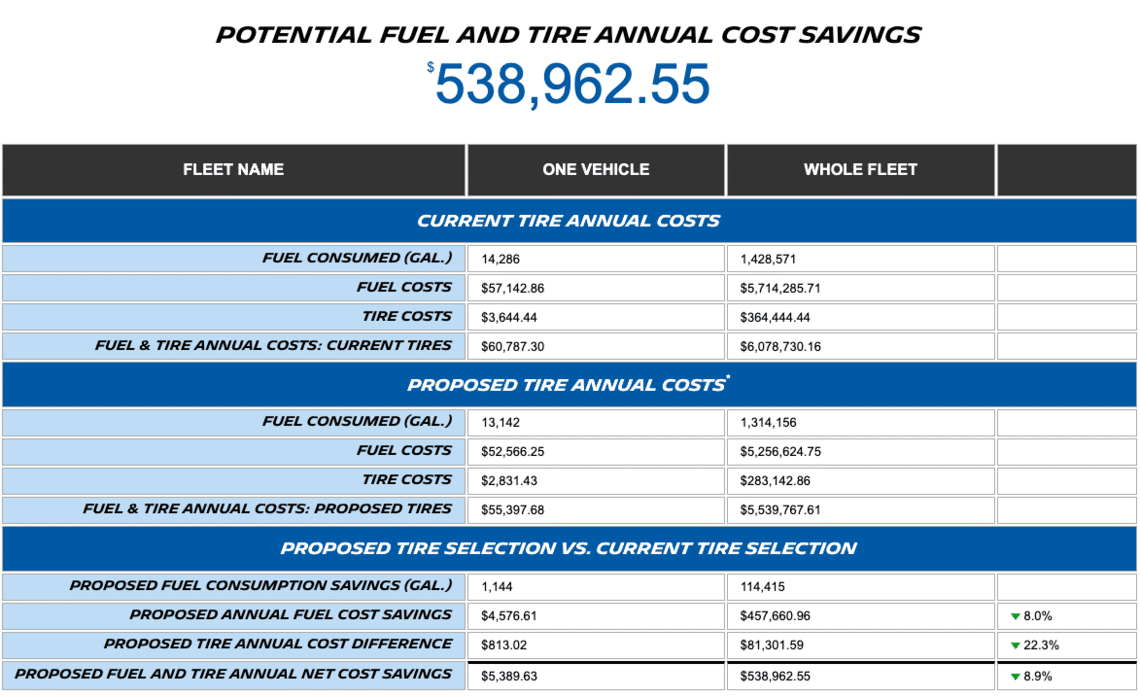

A fleet of 100 6x4 trucks running 100,000 miles per year, at 7mpg, with fuel costing $4/gallon uses $57,143/year in fuel per truck or $5,714,286 for the fleet. In tires they spend $3,644/yr per truck per year or $364,444 annually for the fleet. In this case, fuel expense is more than 15 times the tire expense.

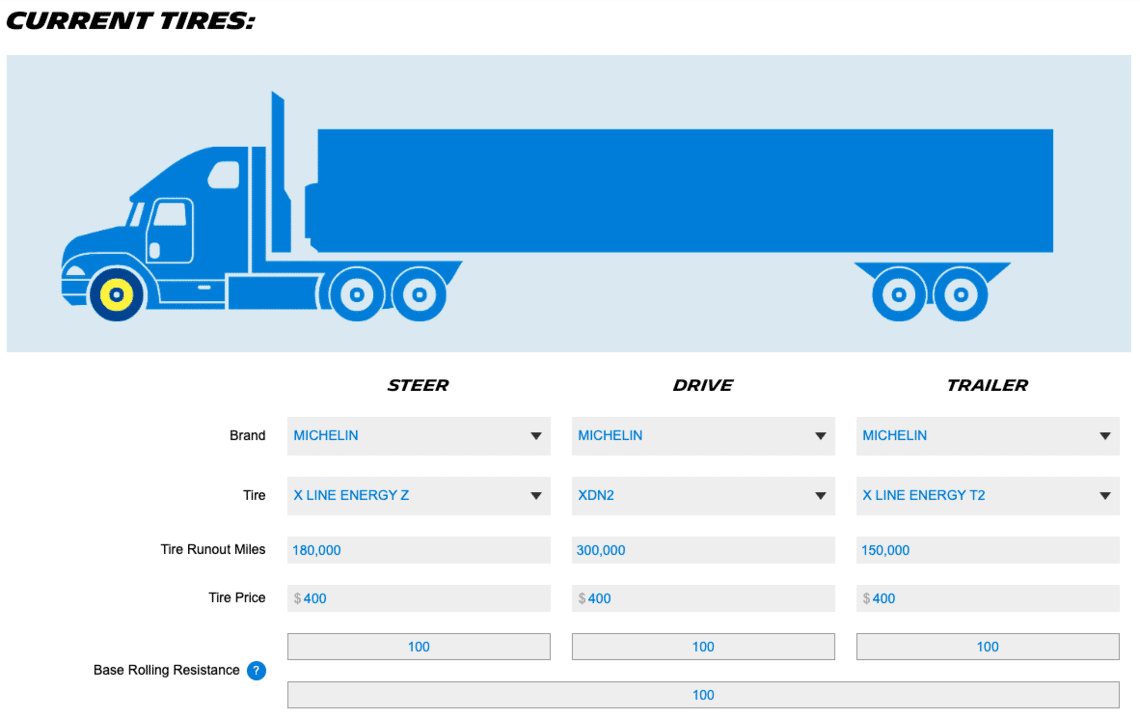

If we will only change the steer and drive tires and leave the trailer the same in both scenarios (since most fleets use retreads on trailer) we can see the difference tires can make in TCO. Initially, we will use Michelin X® Line Energy™ Z steer tires and XDN2 drive tires, the leaders in CPM. We will change the steer tires to Michelin's newest steer tire – Michelin X® Line Energy™ Z+ (XLEZ+), and the drive tires to Michelin X® Line Energy™ D+ (XLED+) tires, the leaders in fuel savings.

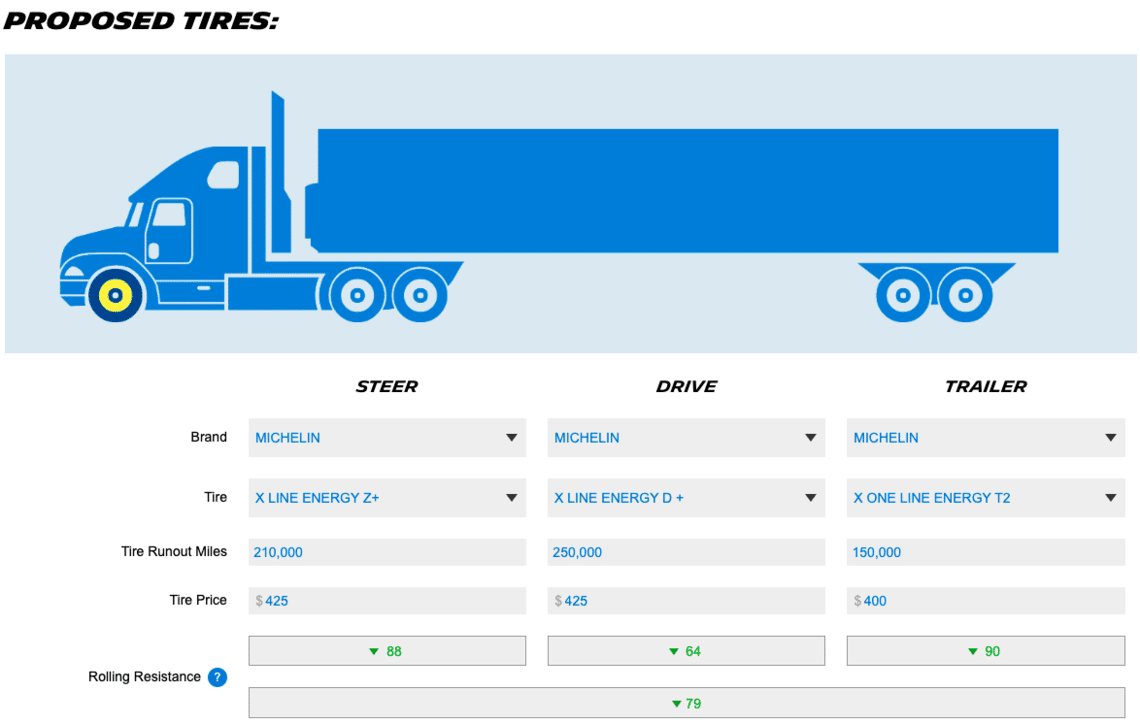

The Michelin X® Line Energy™ Z+ is 12% lower in rolling resistance (RR) and the Michelin X® Line Energy™ D+ is 36% lower in rolling resistance than the XLEZ/XDN2, respectively. We will put in a higher purchase price of +$25 per tire. We will also put a shorter runout miles by 50,000 miles for the Michelin X® Line Energy™ D+ vs the XDN2 (conservative). With the Michelin X® Line Energy™ Z+, Michelin innovations, coming out of the SuperTruck 2 project, increased the mileage by +12%3 over the Michelin X® Line Energy™ Z. Factoring all this in the TCO calculation shows that the XLEZ+/XLED+ can save $4,577 (1,144 gallons) of fuel/yr/truck. Easily offsetting the extra $51 in annual tire costs.

The annual saving per truck is the fuel savings minus the extra tire costs = $5,390/ truck / year or $538,963 for the fleet.

Current tire selection

Fuel-savings calculator screen showing current tire selections for the example provided.

Proposed tires for cost savings

Fuel-savings calculator screen showing proposed tire selections for the example provided.

Potential fuel and tire cost savings

Fuel-savings calculator screen showing the executive summary of potential fuel and tire savings each year based on the example provided.

Should maintenance costs be included in tire TCO?

Tire purchase and fuel costs are the easiest to calculate and the Michelin fuel-savings calculator makes it even easier, you can choose from all the most popular tires and retreads (we have already measured the rolling resistance of all those tires). These two are the biggest factors in tire TCO. The maintenance costs associated with tires is a little more difficult to quantify. However, you could use a standard rate for changing tires and factor that into the TCO based on how long they last.

One of the biggest problems fleets have with using a TCO model to evaluate tire cost has to do with budgets within the fleet. Often there are separate budgets for tires, fuel, and truck maintenance. Each department has separate KOIs and motivations. To bring the fuel costs down you may need to spend more on tires (purchase price and/or CPM). Top fleets have discovered that having separate budgets encourages thinking in silos. Those managing the tire budget don’t have any incentive to save fuel, especially if it raises the tire budget. A fleet needs to find ways to integrate those budgets to think more wholistically about what is best for the fleet

Additionally, going from CPM to TCO will likely have an additional benefit of being more “green." Lower rolling resistant tires save fuel by not burning as much to go the same distance. By burning less fuel we produce less CO2 and that is a good thing. TCO is an important tool a fleet can use to Go the Extra Mile for their bottom line and for everyone’s future.

At Michelin, we don’t feel like we must choose between Planet and Profit, we can have both.

– said Garrett

Michelin X® Line Energy™ Z+ Tire on road

Michelin X® Line Energy™ Z+ tire

Michelin's newest steer tire is setting a new standard in the industry as it offers up to 4 retreads on the casing. The Michelin X® Line Energy™ Z+ tire has 12% lower rolling resistance and delivers 17% more miles than it's predecessor to help fleet owners' bottom line.

1 “An Analysis of the Operational Costs of Trucking” 2019, prepared by the American Transportation Research Institute, November 2019

2 “Factors and Considerations for Establishing a Fuel Efficiency Regulatory Program for Commercial Medium- and Heavy-Duty Vehicles” U.S. Department of Transportation | National Highway Traffic Safety Administration

3 Based on wear projections in an internal study of 5 fleets in line haul usage at 94% worn, 260 total tires, 6/32” pull point, 295/75R22.5 LRH X® Line Energy™ Z+ vs. 275/80R22.5 LRH X® Line Energy Z™ (equivalent sizes). Actual on-road results may vary.