Michelin Better Mining – Innovative Solutions for Safe, Smart and Sustainable Mining

MICHELIN Better Mining – Innovative Solutions for Safe, Smart and Sustainable Mining

Mining is essential to our everyday lives and to build a more sustainable future. The demand for critical minerals and metals is increasing, and miners are under tremendous pressure to produce more and to mine more sustainably.

Whether your goals are to improve mine safety, maximize mining productivity, advance mining sustainability, reduce environmental and social impact, or all of the above, the team at Michelin has innovative offers to help your mines operate safer, smarter and more sustainably.

SAFE - Maximize Mine Safety

Protecting your employees and equipment is critical to you and your business, and one of the many reasons why Michelin prioritizes safety. We know and understand what’s at stake. Tire safety is top of mind from the very beginning at Michelin and brought to life through our excellence in R&D, high-quality materials and industry-leading manufacturing.

See MICHELIN MINING Tire Testing in Action

Michelin is the only tire manufacturer with a dedicated, real-world testing facility for mining tires, located in Almeria, Spain. Using the most advanced technologies, a team of 200 highly qualified specialists put our mining tire innovations through rigorous testing to ensure they are safe, smart and sustainable.

Which MICHELIN mining tires are right for you?

Improve your operations with the right tires for your mining fleet.

From surface mining to underground mining to construction and everything in between, Michelin has the tires you need to get the job done right.

Michelin has a breadth of mining tires for your mining fleet

Michelin’s pursuit of safety does not end with mining tires. We are passionate about helping our customers maximize mine safety with our extensive portfolio of solutions, services and support.

-

Create customized action plans to minimize safety hazards and maximize mine productivity with MICHELIN CONSULTING SERVICES.

-

Train your personnel on mining tire and mining fleet safety. Consider safety training and solutions offered through KLINGE.

-

Proactively detect potential tire and road hazards to avoid incidents, get more life and production out of your tires, minimize vehicle downtime and improve driving conditions for your mining truck operators through MICHELIN MINING SERVICES AND SOLUTIONS.

-

Remotely monitor tire pressure and temperature risks, while keeping mine personnel at a safe distance from mining trucks, with Michelin’s innovative tire pressure and temperature monitoring systems – MICHELIN MEMS SOLUTIONS.

SMART – Boost Mining Productivity

Efficient, safe and cost-effective day-to-day operations are the cornerstone to achieving your mining production targets while complying with safety and environmental regulations. Michelin is here to help you maximize your mining productivity with innovative products, services, solutions and support.

… With MICHELIN Mining Tires

A technological leader in motion, Michelin has a history of innovative firsts. We introduced the mining industry’s first radial earthmover tire in 1959 and then launched the industry’s first 63” tire in 1995, which opened the doors for a whole new category of mining trucks.

Just last year, Michelin introduced the mining industry’s first radial tire for the world’s largest wheel loader, the 70/70R57 MICHELIN X MINE L4** tire for the Komatsu WE2350/P&H L2350.

This tire is designed to improve mobility and productivity thanks to three times the tramming speed of the competitor tire1. In a simulation (2), the loaders with the 70/70R57 MICHELIN X MINE L4** tire arrived at their destination one hour and 20 minutes sooner than loaders equipped with competitor tires. Over the course of a year, loaders equipped with the 70/70R57 MICHELIN X MINE L4** tire have the potential to carry nearly 800,000 more tons of material.

MICHELIN X MINE tire mining productivity for mining fleets and large wheel loaders

Michelin is continuing to evolve its mining truck tire technology to deliver industry-leading energy efficiency and mining productivity improvements—including the support of future vehicle power technologies.

… With MICHELIN Support Team

When you put MICHELIN tires to work for your mining operations, you get more than just innovative tire technology; you gain access to your own Michelin support team of account managers, customer engineering support and service engineers. Michelin support teams combine local mining expertise with global industry experience to boost mining productivity through:

- tire recommendations customized to your mine site conditions.

-

scrap tire analysis to uncover the root causes of scrap tires for customized corrections and recommendations.

-

tire management best practices to maximize safety, improve tire life and boost mining productivity.

-

data-driven insights and recommendations on improvements for better haul road maintenance, optimized truck routes and more.

Michelin support team offers recommendations to boost the productivity of your mining fleet.

… With MICHELIN Consulting & Services

Through proven measurement tools, data-driven insights, expert analysis and innovative solutions, Michelin consultants uncover opportunities and deliver customized offers that reduce tire-related downtime in your mine, amplify mine safety, optimize cycle times and reduce production costs.

Michelin solutions can include:

-

weight studies to help increase your mining truck’s payload and productivity.

-

safety audits, site safety and productivity seminars to proactively identify potential hazards and improve safety and performance across your mine operations.

-

tire consumption and tire rotation studies to minimize mining truck downtime and reduce production costs.

Michelin consultant to support mining productivity, mine safety, mining tires and sustainable mining practices

… With Technologies

Michelin introduced the mining industry’s first tire pressure monitoring system in 2006. Now in its 4th generation, MICHELIN MEMS 4 is an innovative tire pressure monitoring system that drives better mining fleet performance through remotely monitoring tire temperature and pressure and tracking tire usage.

MICHELIN MEMS 4 provides mining fleet data to mines worldwide and is the only monitoring system on the market that, by design, retains historical tire pressure and GPS tracking by tire.

Further, MICHELIN MEMS 4 offers an optional feature: thermal capacity management, which enables you to proactively manage the thermal capacity of each mining truck’s tires to make more informed decisions. This new feature allows you to reroute a hot truck and replace with a cooler truck, schedule tire maintenance to fit your schedule and keep your mine moving, while extending tire life.

Michelin Mining’s tire pressure monitoring system helps mining fleets boost mining productivity

Michelin also offers a simple, budget-friendly tire pressure monitoring system for rigid dump trucks below 150T - MICHELIN MEMS LITE.

MICHELIN MEMS LITE is an entry-level MEMS solution that periodically captures and transmits tire pressure and temperature data.

Learn more about:

… With Breakthrough Tire Management Solutions

We work in partnership with our mining customers to deliver just-the-right suite of solutions that will drive your operations forward, including breakthrough tire management offers.

MICHELIN TK (Tons Kilometer) Solution

This groundbreaking tire management solution evolves the traditional model of mining tire management to one that reduces complexity and optimizes production costs through a pay-by-production model. You can focus on your core business and let Michelin manage your mining tire program end-to-end, from tire maintenance to invoicing.

KLINGE TOTAL TYRE CONTROL™

A proven solution that plans tire maintenance and proactively manages your mine tire and rim budget, Klinge Total Tyre Control™ manages tire bay day-to-day activities, helping improve scheduled versus unscheduled maintenance and tire technician safety.

Learn more about:

Michelin s mining tire management boosts mining productivity

SUSTAINABLE – Reduce Environmental and Social Impact

Sustainable mining means finding the right balance between your economic ambitions and your environmental and social responsibilities. Michelin is committed to working with you to build a more planet-friendly future and advance sustainability in the mining industry. Together, we go farther faster.

… On Our Way to All-Sustainable Tires

Michelin has pledged by 2050 to design and mass produce tires that integrate 100% renewable or recycled materials. This commitment lowers Michelin’s dependence on finite raw materials while aiding in a more circular economy through the increased use of recycled waste. In partnership with leading global companies in recycled and renewable materials, we are laying a roadmap to full circularity by 2050 without compromising the quality or performance of our products.

sustainability in the mining industry with recycled and renewable materials in mining tires

Addressing Environmental Impact During Tire Usage

Based on data from Life Cycle Assessments, up to 90% of our tire’s environmental impacts occur while it’s in use. Understanding what impedes a mining truck’s forward movement is important to address energy efficiency and reducing a tire’s environmental impact.

Michelin is optimizing its mining product and service portfolio to prioritize sustainability and mining productivity. Energy efficiency, including the reduction of rolling and motion resistance, and the proper use of mining tires will help mine fleets reduce fuel consumption, emit less CO2 and lower production costs.

Sustainability in the mining industry with energy efficient mining tires sustainable mining practices

What is a Life Cycle Assessment?

Our products need to have as little impact as possible on the environment over their lifecycles. Michelin uses Life Cycle Assessments to measure the environmental impacts of our tires and services from raw materials to manufacturing to finished-goods shipments to use and end of life. These insights equip our engineers with information needed to continually innovate solutions that advance mining sustainability without compromising product performance.

By 2030, 100% of Michelin's new product will undergo Life Cycle Assessments.

life cycle assessment for sustainability in mining industry and more sustainable mining tires and mining fleets

Leading the Way in End-of-Life Tire Solutions

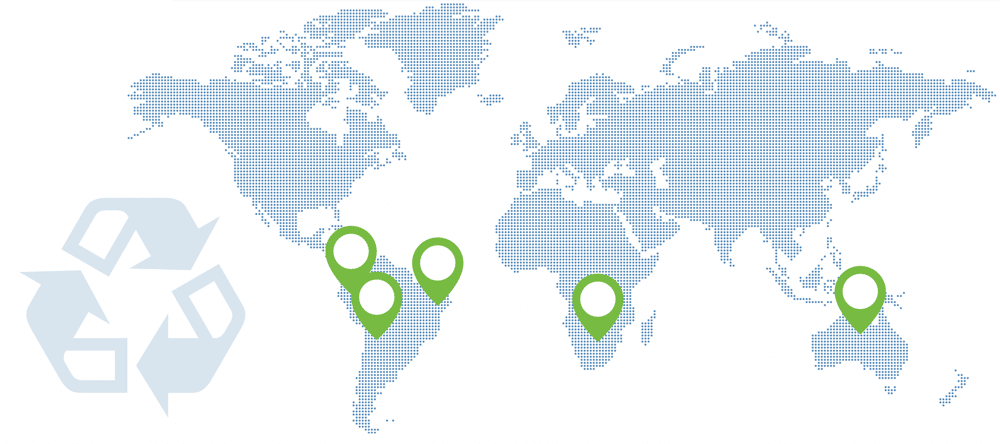

Michelin is working across the mining industry to identify agile solutions that can be adapted to local context for greater impact. These initiatives include:

-

A long-standing recycling partnership with RUBBER BRAS (Brazil)

-

A recently established partnership with NEUMA PERU (Peru)

-

The exploration of opportunities in South Africa, West Africa and Australia

-

Opening Soon – Michelin’s First Mining Tire Cutting and Shredding Facility in Chile

LEARN ABOUT MICHELIN’S TIRE CUTTING AND SHREDDING FACILITY IN ANTOFAGASTA, CHILE

Life cycle assessments

How Can We Help?

MICHELIN Better Mining starts and ends with you – our customer. We innovate to meet your needs with innovative mining offers, including mining tires, services, solutions and support for safe, smart and sustainable mining. How can we help you be safer, smarter and more sustainable? We look forward to talking to you and developing a custom MICHELIN Better Mining offer to address your mining needs.

1 Based on the Firestone® Technical Bulletin reference number BATO-OTR-TB-002-160719, using ambient 38°C and greater than (>) 5 km tramming distance for the 70/70-57 Firestone® SRG DT LD L4 bias ply tire at 4 km/hr compared to the 70/70R57 MICHELIN® X MINE® L4** tire, which demonstrated three times the tramming speed at 12 km/hr. Actual results may vary.

2 Simulation only. Assuming loader productivity rated at 2500 tons in an hour, and tramming distance of 8 km, and based on the Firestone® Technical Bulletin reference number BATO-OTR-TB-002-160719 (GLT Tramming PDF), using ambient temperature of 38°C and greater than (>) 5 km tramming distance, the loader with 70/70-57 Firestone® SRG DT LD L4 bias ply tires takes 2 hours to cover the distance at 4 km/hr, and the loader with 70/70R57 MICHELIN® X MINE® L4 ** tires takes 40 minutes at 12 km/hr, which equates to 798K more tons per year (assuming 5 movements per week and 48 weeks of equipment utilization in a year).