Using bias or radial tires for fertilization

Fertilization: should you use bias tires or radial tires?

While the choice between bias or radial tires is crucial for the entire crop cycle, it is particularly important during the fertilization phase. As we will see, choosing one technology over the other can make all the difference in terms of soil protection. Which one will suit your needs? Find out in this article.

The risk of soil compaction

The fertilization period can be very complicated because of the weather. It's often during wet conditions that you're having to treat or apply fertilizer, which can have a major impact on soil compaction. If the soil is wet, the tires of your machine will compact the soil by crushing the pores and eliminating all the air that's in the micro-porosities. This is where you risk doing the most damage.

The best way to limit this is to work at low tire pressure. In fact, it's recommended that you do this every time you work in the field, whether it’s wet or dry conditions and even outside the fertilization period. When harvesting, for example, the risk of compaction is also high because the machinery used is heavier and compacts the soil.

But it's when you're working in wet conditions that the risk of compaction is increased. Fortunately, the right choice of tire technology can reduce this phenomenon.

The difference between bias and radial tires

Michelin invented radial technology in 1946. Why was this a major innovation? Because the principle of the radial tire is that the sidewalls are separated from the crown. So, when you deflate a radial tire, the sidewalls flatten out. And because the center of the tire is separated from the sidewalls, the area of contact with the ground is extended, taking on a rectangular shape.

On a bias tire, the crown and sidewalls are linked, which creates a domed shape. When the tire is deflated, this impacts the tread as much as the sidewalls, which means that the shape of the contact patch with the ground is elliptical, making it smaller than on a radial tire.

The advantage of radial ag tires is that by lowering the pressure, the tire's footprint on the ground is longer, and as the load is spread over a larger surface area, it is less per square inch.

How does this longer footprint benefit you? It brings several benefits:

- less soil compaction

- improved traction, which means lower fuel consumption and greater productivity

- greater comfort (the wider distribution of rubber on the ground means better shock absorption)

Do radial tires last longer than bias tires?

There are two aspects to tire life: impact resistance and endurance.

A bias tire is more resistant to impacts because it contains several carcasses. On the other hand, it heats up a lot when it is under heavy stress, particularly during the fertilization phase when the tanks are heavy and the tires narrow.

A radial farm tire, which has only one carcass, deforms less and dissipates more heat, which makes it better in terms of thermal resistance. They are designed to be more durable than bias tires, because they have a greater surface area in contact with the ground.

The radial’s larger footprint means that the load is distributed more evenly, and consequently, the wear is more uniform and results in longer tire life. A bias tire, which has an elliptical ground surface, is subject to local overpressure, which tends to make it wear more quickly.

Radial tire + Michelin UltraFlex technology = the combination you need

While the advantages of radial tires are undeniable, they can bring further benefits by choosing radial tires equipped with Michelin UltraFlex technology.

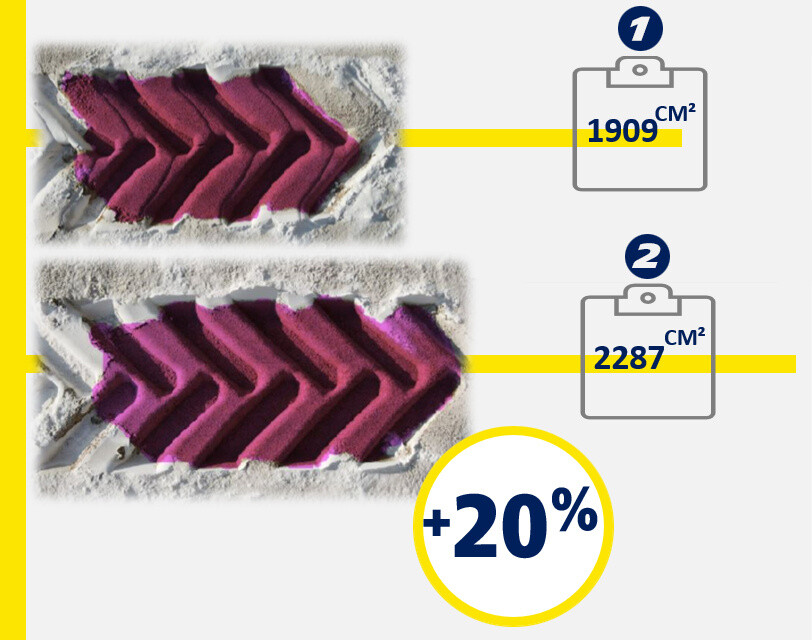

In fact, a test has shown that between a Michelin radial tire with Michelin UltraFlex technology and a competitor's radial tire, the Michelin SPRAYBIB tire has 20% more footprint *:

20% more footprint with MICHELIN SPRAYBIB tyre, with MICHELIN UltraFlex and radial technologies*

1 : The footprint of a competitor's radial tire with standard technology (dimension: 380/90 R46 172D/175A8)

2 : The footprint of the Michelin SPRAYBIB tire, a radial tire of the same dimensions, designed with Michelin UltraFex technology.

In this test*, the competitor's tire covers 296 inch2 (1909 cm2) whereas Michelin SPRAYBIB tire covers 355 inch2 (2287 cm2), which is 20% more ground surface.

In other words, when the competitor's tire exerts a pressure of more than 5,530 tons per square foot (27 tons per m2) on the ground, the Michelin SPRAYBIB tire should typically reduce it by 922 tons per square foot (4.5 tons per m2), which means better soil protection, better traction and fuel savings.

MICHELIN SPRAYBIB radial tyre

We offer several radial tires with Michelin UltraFlex technology, each adapted for a different piece of farm machinery:

- The Michelin YIELDBIB tire for tractors

- The Michelin SPRAYBIB tire for self-propelled sprayers

- The Michelin FLOATXBIB tire for self-propelled spreaders

Save fuel with adapted pressure

The three ranges of Michelin UltraFlex radial tires mentioned above are also compatible with the CTIS (Central Tire Inflation System)(**). With CTIS equipped, you can use this system to adjust tire pressure without leaving the cab of your vehicle, so that it's always at the optimum level no matter the terrain or your use.

Optimized tire pressure means you get all the benefits your tires can deliver (very low pressure with Michelin UltraFlex technology, less soil compaction, better traction) and avoid unnecessary fuel costs.

Need more advice? Discover our tire buying guide.

* Internal Michelin study carried out in Arbonne - France in January 2022. Competitor tyres 380/90 R46 172D/175A8 and MICHELIN SPRAYBIB VF tyres 380/90 R46 CFO 173D/169E. The load per tyre is identical: 5200kg and the pressures used are those recommended by each manufacturer: 3.2b for the competitor tyre and 2.3b for the MICHELIN SPRAYBIB CFO tyre.

** CTIS is only available in certain countries. Ask your dealer for further information.